What is the Difference Between Hot Melt and PUR?

When it comes to adhesives, two popular options are Hot Melt and Polyurethane Reactive (PUR) adhesives. While both serve similar purposes in bonding materials, they have distinct properties, applications, and advantages. Understanding these differences can help you choose the right adhesive for your project.

What is Hot Melt Adhesive?

Hot melt adhesive is a thermoplastic adhesive that is applied in a molten state. It solidifies upon cooling, forming a strong bond between surfaces. Here are some key characteristics:

l Application Temperature: Typically applied at temperatures between 250°F to 400°F (121°C to 204°C).

l Curing Time: Fast curing time, often achieving initial bond strength within seconds.

l Versatility: Suitable for a variety of substrates, including wood, paper, plastics, and metals.

l Reworkability: Can be re-melted and adjusted if needed, making it flexible for adjustments during assembly.

Common Applications of Hot Melt Adhesives

l Packaging

l Automotive assembly

l Furniture manufacturing

l Bookbinding

What is PUR Adhesive?

Polyurethane Reactive (PUR) adhesives are a type of moisture-curing adhesive that combines the properties of both polyurethane and hot melt adhesives. They offer several unique features:

l Curing Mechanism: PUR adhesives cure through a reaction with moisture in the air, leading to a more robust bond.

l Flexibility and Durability: Once cured, PUR adhesives provide excellent flexibility and resistance to environmental factors, such as heat and moisture.

l Initial Bond Strength: While they may take longer to achieve full strength compared to hot melts, PUR adhesives offer superior long-term durability.

Common Applications of PUR Adhesives

l Woodworking

l Flooring installation

l Automotive interior bonding

l Assembly of high-performance products

Key Differences Between Hot Melt and PUR Adhesives

Feature | Hot melt adhesive | PUR adhesive |

Curing Method | Cools and solidifies | Cures with moisture |

Initial Bonding | Fast(seconds to minutes) | Moderate(hours for full strength) |

Heat Resistance | Moderate | High |

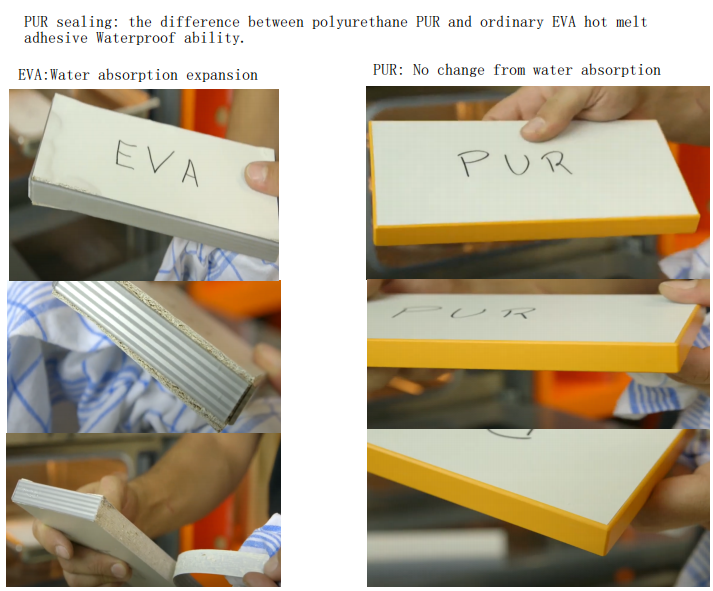

Moisture Resistance | Limited | Excellent |

Flexibility | Rigid after cooling | Flexible and elastic after curing |

Choosing the Right Adhesive

When deciding between hot melt and PUR adhesives, consider the following factors:

1. Project Requirements: Assess the environmental conditions the bond will be exposed to, including temperature and moisture.

2. Speed of Application: If quick bonding is essential, hot melt may be the better choice.

3. Material Compatibility: Ensure the adhesive is suitable for the materials being bonded.

4. Long-Term Performance: For applications requiring durability and flexibility, PUR adhesives may be more appropriate.

Conclusion

Both hot melt and PUR adhesives have their unique advantages and applications. Understanding the differences between these two types of adhesives will help you make an informed decision for your specific needs. Whether you prioritize speed, flexibility, or environmental resistance, there is an adhesive solution that meets your requirements.

For more information on adhesive technologies and their applications, feel free to reach out or explore further resources.