Ten Tips for Working with Polyurethane Reactive (PUR) Hot Melt

Polyurethane Reactive (PUR) hot melt adhesives are renowned for their superior bonding capabilities and versatility in various applications. Whether you’re in woodworking, packaging, or automotive assembly, mastering the use of PUR adhesives can lead to better results. Here are ten essential tips to help you work effectively with PUR hot melts.

1. Know the Benefits of PUR Adhesives

Understanding the advantages of PUR adhesives is the first step in leveraging their potential. PUR adhesives offer exceptional bond strength, flexibility, and resistance to temperature fluctuations and moisture. They are ideal for applications requiring durable, long-lasting bonds.

2. Familiarize Yourself with Properties

PUR adhesives are moisture-curing, meaning they require humidity to cure effectively. This property makes them unique compared to traditional hot melts. Knowing how these adhesives react to environmental conditions will help you choose the right product for your specific needs.

3. Prepare Your Workspace

A clean and controlled workspace is crucial for working with PUR hot melts. Ensure that your environment is dry and well-ventilated. High humidity can interfere with the curing process, leading to subpar bond strength. Maintaining consistent temperatures also aids in achieving optimal performance.

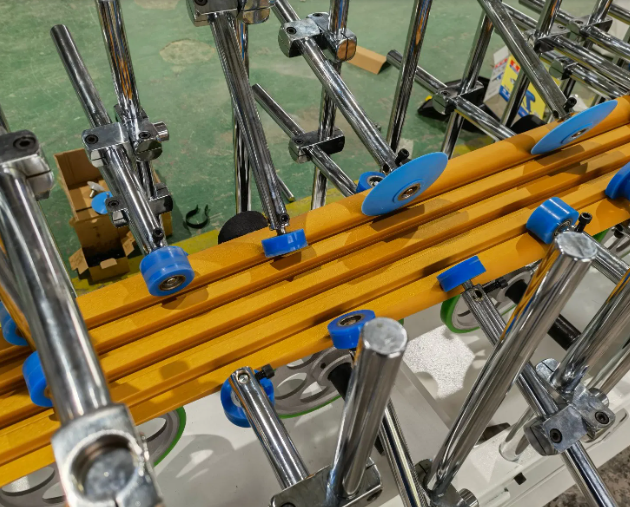

4. Select the Right Application Equipment

Using the appropriate application equipment is essential for successful bonding. Invest in a hot melt glue gun designed specifically for PUR adhesives. Ensure it can maintain the required temperature and has the correct nozzle size for your application to minimize waste and improve efficiency.

5. Ensure Proper Surface Preparation

Surface preparation is key to achieving strong bonds with PUR adhesives. Clean all surfaces thoroughly to remove dust, grease, and contaminants. For porous materials, consider using a primer to enhance adhesion. Properly prepared surfaces will result in stronger, more durable bonds.

6. Control Adhesive Temperature

Maintaining the right adhesive temperature is critical. PUR hot melts should be heated to the manufacturer’s recommended temperature for optimal flow and adhesion. Overheating can degrade the adhesive, while underheating may prevent proper bonding.

7. Apply the Right Amount of Adhesive

Applying the correct amount of adhesive is essential for achieving strong bonds. Too little adhesive may result in weak joints, while too much can lead to overflow and mess. Practice the right application technique to ensure even coverage without excess.

8. Monitor Humidity Levels

Since PUR adhesives cure in the presence of moisture, be mindful of humidity levels in your workspace. Aim for a balanced environment, as too much or too little humidity can affect curing times and bond strength. Use a hygrometer to monitor conditions accurately.

9. Allow Sufficient Curing Time

After applying the adhesive, give it adequate time to cure. While PUR adhesives often cure quickly, environmental factors can influence this process. Avoid stressing the bond until it has fully cured to ensure maximum strength and durability.

10. Test Bond Strength

Before moving forward with your project, conduct a bond strength test on a sample piece. This step will help you confirm that the adhesive is performing as expected and will allow you to make any necessary adjustments to your process or materials.

Conclusion

Working with Polyurethane Reactive hot melt adhesives can elevate the quality of your projects when done correctly. By following these ten tips—understanding the benefits and properties, preparing your workspace, selecting the right equipment, and monitoring application conditions—you can achieve strong, reliable bonds in your work. Embrace the versatility of PUR adhesives and enhance your project outcomes!