Comparing Waterproof Glues: Advantages of PUR Hot Melt Adhesives Over PVA and Epoxy

When it comes to bonding materials in environments exposed to moisture, choosing the right adhesive is crucial. Among the options available, PUR hot melt adhesives, PVA (polyvinyl acetate), and epoxy each have their strengths and weaknesses. In this article, we will explore the advantages of PUR hot melt adhesives, particularly in terms of waterproofing, durability, and application versatility.

Understanding the Types of Adhesives

1. PVA (Polyvinyl Acetate)

PVA is a water-based adhesive commonly used in woodworking and crafts. It offers ease of use and quick drying times. However, its performance in wet conditions is limited, making it less suitable for outdoor projects or areas with high humidity.

2. Epoxy

Epoxy adhesives are known for their strong bond and resistance to chemicals and heat. They consist of two components that must be mixed prior to application. While epoxy provides excellent waterproofing, its curing time can be lengthy, and the application process can be cumbersome.

3. PUR Hot Melt Adhesives

PUR (polyurethane reactive) hot melt adhesives have gained popularity for their superior bonding capabilities and waterproof properties. Unlike traditional hot melts, PUR adhesives react with moisture in the air to create a strong, flexible bond.

Advantages of PUR Hot Melt Adhesives

1. Superior Waterproofing

One of the standout features of PUR hot melt adhesives is their exceptional waterproofing ability. Once cured, they form a robust barrier against moisture, making them ideal for outdoor applications or projects in humid environments. In contrast, PVA adhesives are not waterproof, and while epoxy performs well, it can be more challenging to apply.

2. Fast Curing Time

PUR adhesives cure quickly when exposed to moisture, significantly reducing downtime. This rapid curing time allows for faster project completion, making them ideal for high-volume manufacturing and assembly processes.

3. Versatility in Application

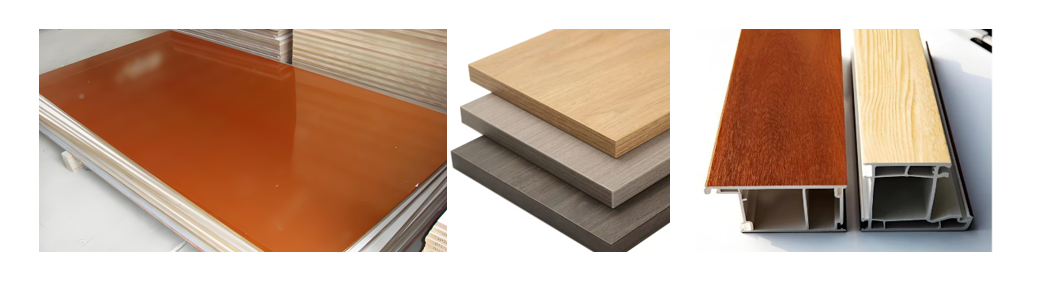

PUR hot melt adhesives can bond a wide range of materials, including wood, plastics, metals, and even textiles. This versatility makes them suitable for various industries, from furniture manufacturing to packaging.

4. Stronger Bonds

The chemical structure of PUR adhesives provides a stronger bond compared to PVA and epoxy. This strength not only improves the longevity of the bond but also enhances the overall durability of the finished product.

5. Environmentally Friendly Options

Many PUR adhesives are available in low-emission formulations, making them a more environmentally friendly choice. This is particularly important in industries where VOC (volatile organic compounds) regulations are stringent.

Conclusion

When comparing waterproof glues, PUR hot melt adhesives emerge as a clear winner in many applications. With superior waterproofing capabilities, fast curing times, and versatility, they outshine traditional options like PVA and epoxy. For projects requiring reliable adhesion in damp environments, PUR hot melt adhesives are the go-to solution.

Consider your specific needs and the materials you are working with to choose the best adhesive for your project. Whether you are a DIY enthusiast or a professional in manufacturing, understanding the advantages of these adhesives can lead to better results and more durable products.